Springs are ubiquitous in our everyday lives, yet their fundamental mechanics are often overlooked. These ingenious devices play a crucial role in various applications, from mattresses to car suspensions, showcasing the fundamental principles of physics and engineering at work.

At its core, a spring is a flexible, elastic object that stores mechanical energy when compressed or stretched and releases it when the force is removed. Let’s delve into the mechanics of how springs work.

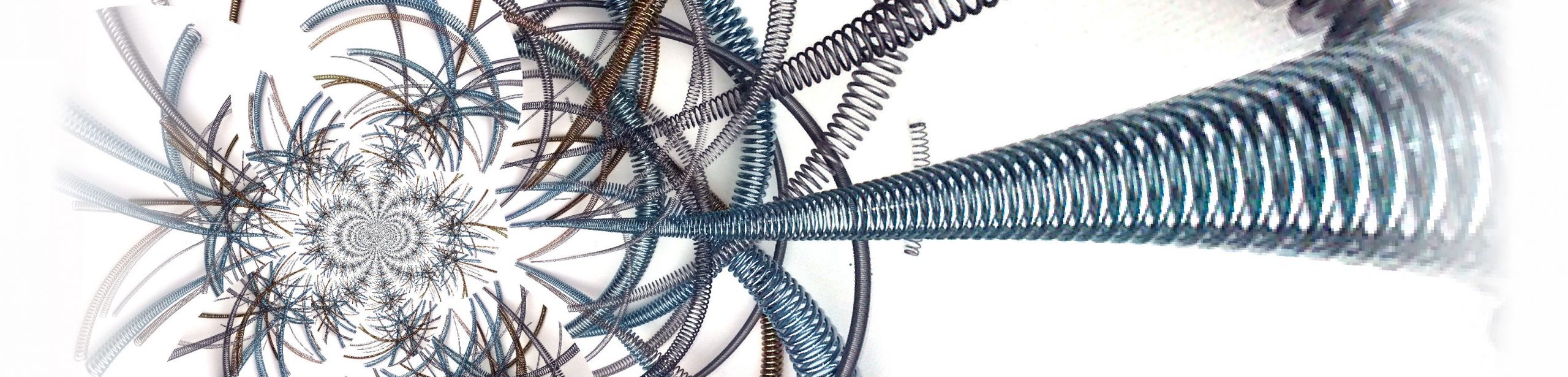

**1. ** Material and Structure: Springs are typically made of materials with high elasticity, such as steel, which can deform under stress and return to their original shape when the force is removed. The shape and structure of a spring are designed to maximize this property.

2. Elasticity: Elasticity is a material’s ability to return to its original shape after being deformed. When a force is applied to a spring, it undergoes deformation—compression or stretching—causing the atomic or molecular bonds within the material to stretch or contract. As the force is released, these bonds pull the spring back to its original position, releasing the stored energy.

3. Hooke’s Law: Hooke’s Law, named after the scientist Robert Hooke, describes the relationship between the force applied to a spring and the resulting deformation. It states that the force required to deform a spring is directly proportional to the amount of deformation produced, within the elastic limit of the material.

4. Compression and Tension: Springs can work in two primary ways: compression springs and tension springs. A compression spring compresses when a force is applied to it, whereas a tension spring stretches when a force is exerted.

5. Energy Storage and Release: When a spring is compressed or stretched, it stores potential energy within its structure. This energy is proportional to the amount of deformation and the spring constant, a characteristic property of the spring material and design. When the force is released, the spring returns to its original shape, converting the potential energy back into kinetic energy.

6. Applications: Springs are utilized in numerous applications, ranging from simple coil springs in pens to complex springs in machinery, vehicles, and buildings. They provide shock absorption, support, and movement control, making them indispensable in engineering and manufacturing.

In conclusion, springs demonstrate the fascinating interplay of physics and engineering, showcasing how materials with elastic properties can be harnessed to store and release energy efficiently. Understanding the mechanics of springs is essential for designing and utilizing them effectively across a multitude of applications, contributing to our everyday comfort and the functionality of countless devices.