Technical

Firstly, please note. I am not a technician, below is what I have found on Google!

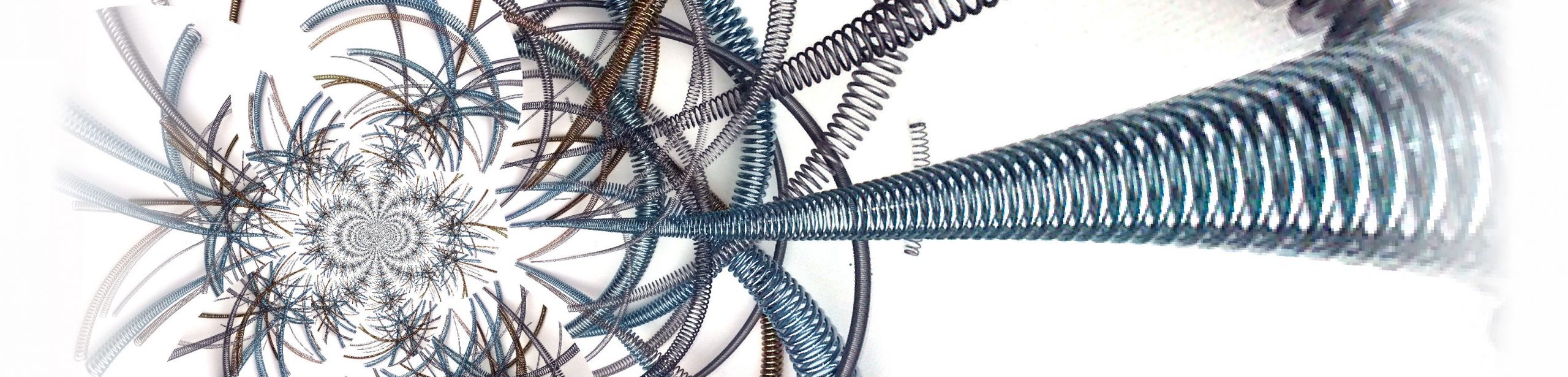

Hooke’s law

As long as not stretched or compressed beyond their elastic limit, most springs obey Hooke’s law, which states that the force with which the spring pushes back is linearly proportional to the distance from its equilibrium length:

where

- x is the displacement vector – the distance and direction the spring is deformed from its equilibrium length.

- F is the resulting force vector – the magnitude and direction of the restoring force the spring exerts

- k is the rate, spring constant or force constant of the spring, a constant that depends on the spring’s material and construction. The negative sign indicates that the force the spring exerts is in the opposite direction from its displacement

k or Spring rate refers to the amount of weight (Lbs/Newtons) that is needed to compress a spring one inch/mm.

To calculate the rate –

k=Gd4 / (8nD3)

Where:

k = constant, pounds of load per unit of deflection

G = modulus of rigidity of spring material

d = wire diameter

n = number of active coils, which is the number of coils subjected to flexure (always less than the total number of coils)

D = mean coil diameter = Outer Diameter – Wire Diameter

G for stainless steel = 70300

G for carbon steel = 79300

Some conversions

1″=24.4mm

1Kg=9.806N

1lb=4.448N

1Kg=2.205lb

Non technical

A Rate of 1 is very soft and 50 is very hard.

Or to put it another way, the larger the number, the stronget the spring is.